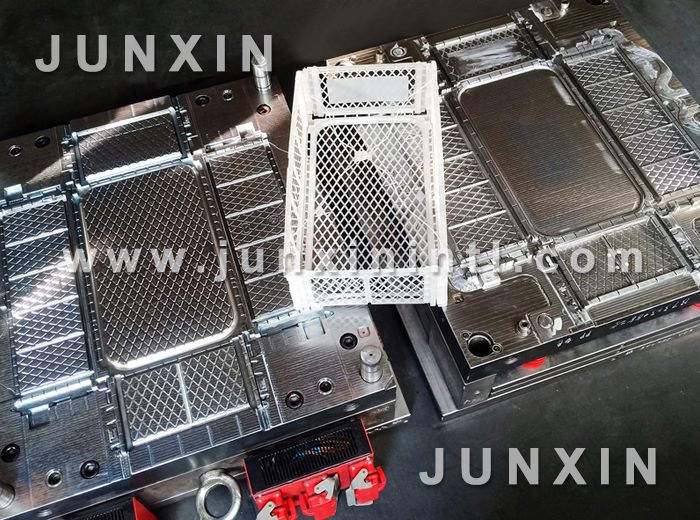

JX-5003

Mould Information:

Part Material: PP, PE

Mould Steel: P20; 718H etc.

Mould Cavities: Single

Mould Injection Gate: Cold runner big gate

Surface Finishing: Mirror polishing

Mould Base: S45C

Cycle Time: 20-30S

Mould Life: More than 500K shots

Suitable Injection Machine: 160-300T

Mould Features: Full automaticity, Fine cooling system

Plastic crate moulds refer to the molds used in the manufacturing process of plastic crates. These crates are widely used in various industries, including agriculture, food processing, and transportation. The process of manufacturing plastic crate moulds is a complicated and technical one, and it requires precision and expertise.

Designing the Mould

The first step in the manufacture process of plastic crate moulds is designing the mould. This process involves taking into account the dimensions and specifications of the crate and designing a mould that will produce crates of the required size and shape. The mold designer uses a software program to create a virtual 3D model of the mold.

Manufacturing the Mould

Once the design process is completed, the actual manufacturing process of the mould begins. The manufacturing process can involve different techniques depending on the type of mould being made. In the case of plastic crate moulds, the most commonly used technique is injection molding.

The injection molding process involves the use of a heated resin material, which is injected into the mould cavity. The liquid resin material fills the cavity and takes the shape of the mould. The resin material then cools and solidifies, and the finished plastic crate is ejected from the mould.

The process of injection molding can prove to be particularly challenging when making plastic crate moulds, as the molds are required to produce crates that are strong and durable, and can withstand the rough handling that these crates are subjected to.

Quality Control

The manufacturing process of the plastic crate moulds must be monitored to ensure that the final product meets the required quality standards. Quality control is carried out at different stages of the process, starting from the design phase to the finished product.

The quality control process checks various aspects of the mould, including the dimensions, surface finish, tolerance, and durability. The finished plastic crate must meet the required specifications and must be able to withstand the environmental factors it will be exposed to.